Home » “Buffered” Coco: The invisible ally for a perfect crop start

A technical article for growers and producers seeking maximum stability and predictability in their substrates.

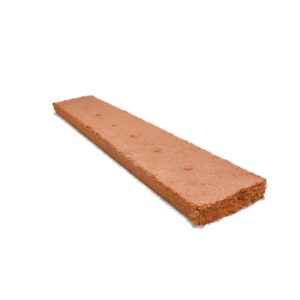

In just two decades, coconut fiber has become the preferred substrate for thousands of growers in soilless systems. Its combination of porosity, oxygenation, water-holding capacity, and structural stability makes it a sustainable alternative to materials such as rockwool.

These properties are well documented: coconut fiber stands out for its high water retention capacity, good aeration, and slow degradation, allowing it to be used over multiple crop cycles.

However, there is a lesser-known factor that, when properly managed, further enhances coco’s performance: its natural chemical composition. This article clearly and practically explains why “buffered” coco provides direct field benefits, how the process is carried out, and why more and more producers are requesting it pre-treated at origin.

Technical note: although the term bufferización does not formally exist in Spanish, it is widely used by technicians as an adaptation of the English term buffering, which describes the treatment of coco with calcium.

Table of Contents

ToggleUnlike other inert materials, coconut fiber contains its own ions, such as potassium (K⁺) and sodium (Na⁺). Some of these ions are free, while others are bound to the negative charges within the structure of the material.

This chemical behavior is not exclusive to coco: any material with cation exchange capacity (CEC) behaves in a similar way. The advantage lies in harnessing this property in favor of the crop through buffering.

Buffering is a pre-treatment that nutritionally stabilizes coco coir fiber before transplanting. It consists of exchanging the natural cations in coco (K⁺ and Na⁺) for calcium (Ca²⁺) and, in some cases, magnesium (Mg²⁺), using a controlled nutrient solution.

The result is a calcium-loaded substrate that provides a predictable, stable medium fully compatible with modern fertigation systems.

Manufacturers typically offer three commercial types:

Unwashed coco

Washed coco (reduction of free salts)

Buffered coco (K⁺ and Na⁺ exchanged for Ca²⁺)

The goal of buffering is not to correct a defect, but to optimize the chemical properties of coco, ensuring more stable nutrition from day one.

Direct and proven advantages for growers

This depends on the grower’s volume and organization:

Buying pre-buffered coco

Ideal for professional horticulture. It guarantees homogeneity, saves labor, minimizes the risk of errors, and delivers consistent results.

On-crop buffering

Possible for those purchasing untreated or washed coco. It allows savings on substrate costs, in exchange for dedicating time and space to the process.

Hydrate the cococoir fiber with clean water or a wetting-agent solution until it expands, though not necessarily to 100%.

Prepare a calcium nitrate solution in controlled proportions.

Rehydrate the fiber with the solution and let it rest for 24–48 hours to allow cation exchange to occur and reduce free Na⁺ and K⁺.

Drain excess solution and rinse with water until electrical conductivity is reduced to suitable levels.

The substrate is then balanced and ready for use, ensuring predictable and safe results from the very start of the crop.

Buffered coco is an invisible ally for producers seeking stable and predictable crop starts, with uniformity, nutrient availability, and immediate compatibility with fertigation. It optimizes coco’s potential from day one and simplifies crop management, saving time and reducing risk.