Blueberries are a popular fruit known for their sweet and tangy flavor, as well as their numerous health benefits. With the rise of hydroponic commercial farming, it’s a “must” cultivating blueberries in a controlled environment, ensuring optimal growth and production.

When setting up a hydroponic blueberry growing system, it is recommended to consult with experts or experienced growers to ensure that you choose the right growing system for your specific needs. They can provide valuable ideas and advice based on their own experience.

Successful hydroponic blueberry cultivation requires careful consideration of the hydroponic system chosen, selection of the right blueberry varieties and optimization of nutrient solutions. By choosing the right system, growers can create an ideal environment for your blueberries to thrive and maximize their production.

For more information about hydroponic blueberry cultivation and best practices and substrate solutions for blueberries, please contact us at here.

Additionally, selecting the right varieties that are known for their adaptability to Open Top, Growing bag or container cultivation will ensure successful growth in a hydroponic setup. It is recommended to source blueberry plants from reputable nurseries or suppliers specializing in hydroponic blueberry production.

PELEMIX offers excellent quality Coco Coir and different Coir & Substrates

1. Blueberry Blend – 3B (Open Top 30 x 30 x 30 – 27 L)

- Our 3BMulti-Drain OpenTop bags System for hydroponic blueberries, raspberries and other berries has been created by combining the ideal volume of a specially formulated coco-coir blend and an innovatively designed Pelemix OpenTop bag.

- Higher yield compared to growing in the ground.

- 3B open Top replaces more expensive pots/containers.

- Pots and containers sterilization is not required

- Earlier harvest due to quicker fruit development

- Labor saving solution – easy installation

- More plants per hectare and high drainage capacity (From 5000 pl/ha in soil up to 9000 pl/ha (RedAgricola, 2017).

- The Open Top 30x30x30 (Bluekit 3B) consists of a black & white bag with 100% coconut fibre susbstrate, ideal for commercial blueberry production.

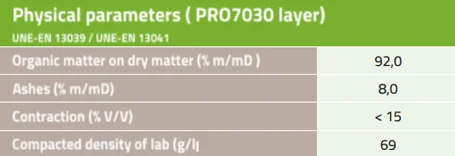

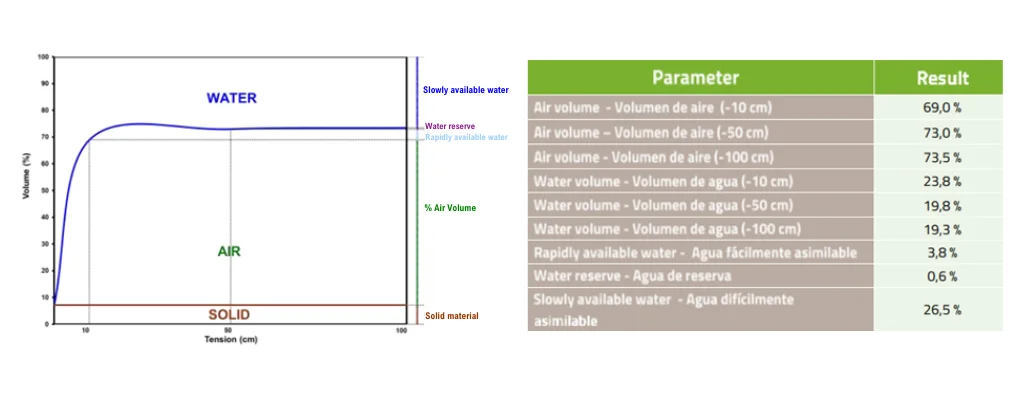

- Coconut fibre has two configurations: Multidrain lower layer and PRO7030 upper layer with a high compact content of coconut chips. Both layers provide excellent drainage and favor the root development of the blueberry plant.

- Waste and Toxic free

- Free from weeds and diseases.

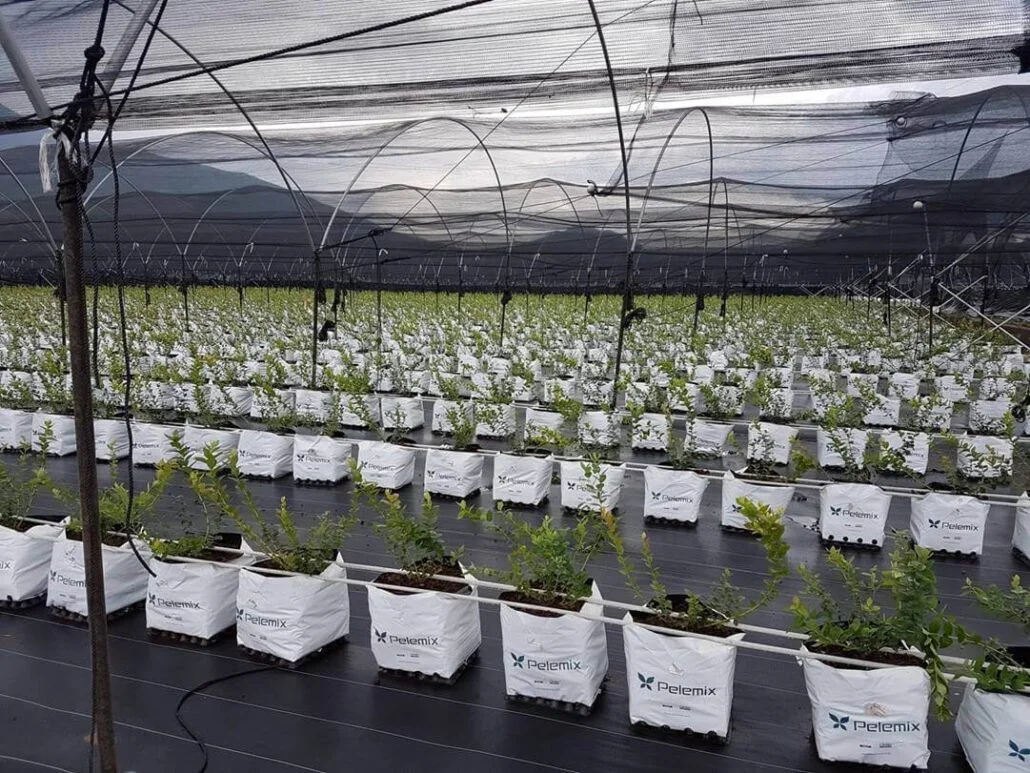

Figure: Blueberry blend Open Top (3B) + Blueberry field with 3B Open Tops

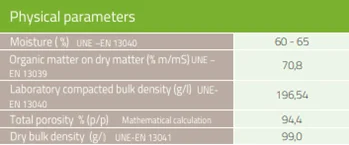

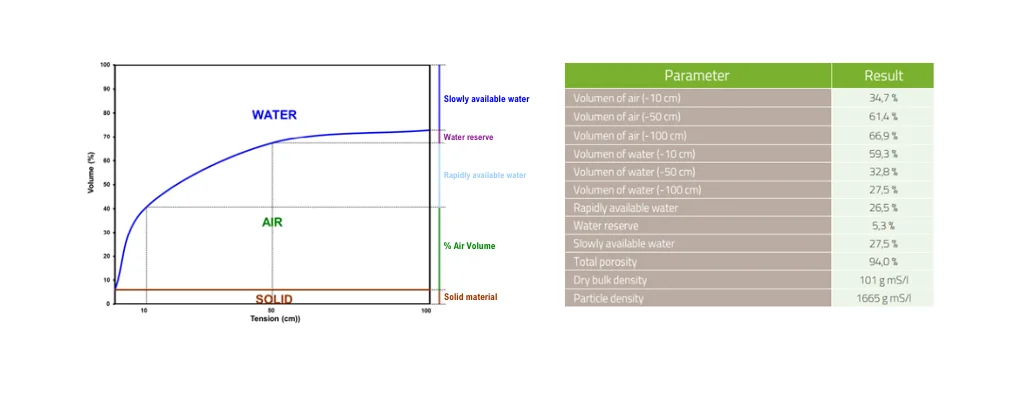

Figures: Physical Parameters (1) + Water Retention Curve (2) + 3B Open Top + Layers (3)

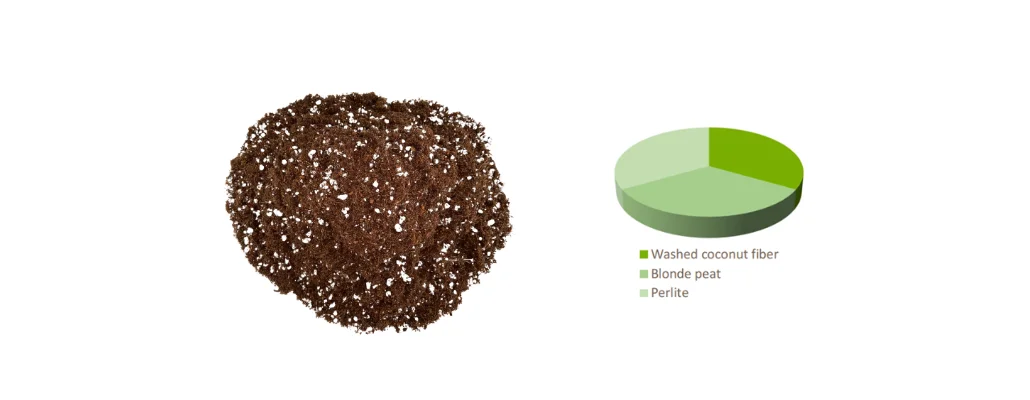

2. Blueberry King

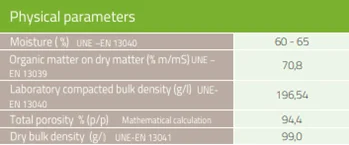

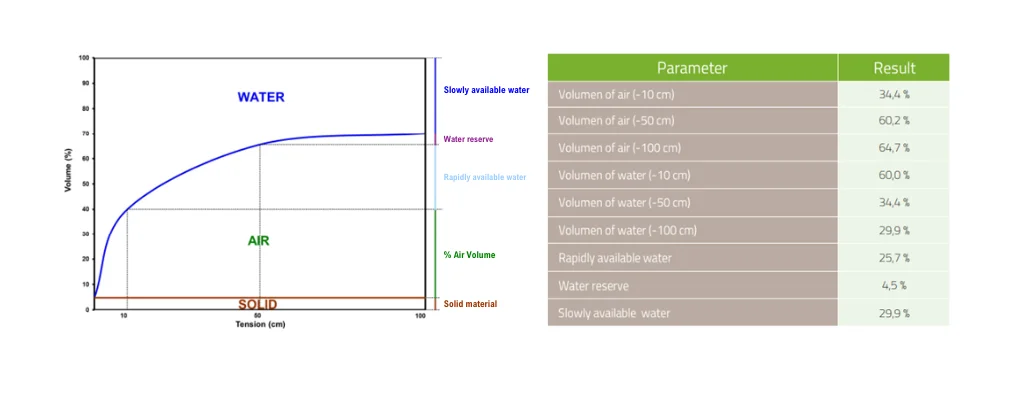

- Mixture of washed coconut fiber, blonde peat and perlite. Ideal for the production of blueberry in container.

- Specially designed by the R & D Department of Pelemix in collaboration with different producers, with the object of providing the blueberry plant a high percentage of aeration, a great drainage capacity and a pH according to their specific needs.

- No residual compounds or chemicals.

- Free of weed seeds.

- Does not carry diseases or pathogens

Figures: Physical Parameters (1) + Water Retention Curve (2) + Blueberry King Substrate (3)

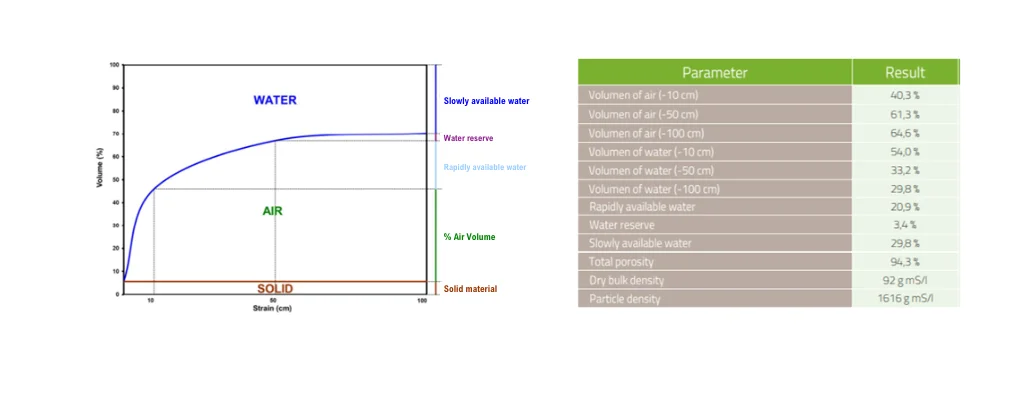

3. Blueberry TECH

- Coconut fiber and blonde peat mix, is the evolution of the Blueberry KING mix for growing blueberry in container.

- Designed with a coarse granulometry of coconut, it allows to eliminate the perlite from the mixture obtaining the same conditions of aeration and drainage capacity.

- No residual compounds or chemicals.

- Free of weed seeds.

- Does not carry diseases or pathogens

Figures: Physical Parameters (1) + Water Retention Curve (2) + Blueberry Tech Substrate (3)

4. Blueberry START

- It’s a blend of washed coconut fiber, blonde peat and perlite. Designed specifically for the production of blueberry in the seedbed.

- Given its composition, it provides optimal aeration, drainage, salinity and pH

- conditions for the root development of blueberry seedlings.

- No residual compounds or chemicals.

- Free of weeds seeds.

- Does not carry diseases or pathogens.

Figures: Physical Parameters (1) + Water Retention Curve (2) + Blueberry Start Substrate (3)

Figure: Pelemix Open Tops Blueberries

OPTIMIZING NUTRIENT SOLUTIONS

Blueberry cultivation in a hydroponic system involves growing the plants in a substrate, such as Cococoir or Coir &Peat substrates, instead of traditional soil. This method offers several advantages, including better control over nutrient delivery and water management, resulting in higher yields and healthier plants.

When it comes to hydroponic blueberry cultivation, optimizing nutrient solutions is crucial for ensuring healthy plant growth and maximizing fruit production. Blueberries are known for their high nutrient requirements, and providing them with the right balance of elements is essential for their overall development.

Monitoring and Adjusting pH Levels

Blueberries prefer slightly acidic conditions, with a pH range between 4.5 and 5.5. Monitoring and adjusting the pH of the nutrient solution is crucial for optimal nutrient uptake. pH levels that are too high or too low can lead to nutrient deficiencies or toxicities, affecting plant health and productivity (Jiang et al., 2019).

Regularly testing the pH of the nutrient solution using a pH meter or test kit is recommended. If the pH deviates from the desired range, adjustments can be made by adding pH-up or pH-down solutions. It is important to make gradual changes and retest the pH until the desired level is achieved.

Choosing the Right Nutrient Solution

The first step in optimizing nutrient solutions for hydroponic blueberry cultivation is selecting the right formula. Blueberries have specific nutrient requirements, and a balanced solution is necessary to meet their needs. It is recommended to use a specialized blueberry fertilizer that contains the essential elements in the correct proportions.

Blueberry fertilizers typically contain nitrogen, phosphorus, potassium, and micronutrients such as iron, manganese, and zinc. These nutrients are essential for promoting healthy growth, flower formation, and fruit development. It is important to follow the manufacturer’s instructions for proper application rates and frequency.

Providing Essential Micronutrients

In addition to the primary macronutrients, blueberries require specific micronutrients for proper growth and development. These include iron, manganese, zinc, and copper. While these micronutrients are present in most blueberry fertilizers, it is important to ensure their availability in the nutrient solution.

Regularly monitoring the nutrient solution for micronutrient deficiencies is crucial. If deficiencies are detected, foliar sprays or targeted nutrient supplements can be used to address the issue. It is important to consult with a horticulture specialist or refer to the fertilizer manufacturer’s recommendations for proper application.

Optimizing nutrient solutions is a key aspect of successful hydroponic blueberry cultivation. By providing the plants with the right balance of essential elements, monitoring pH levels, and addressing micronutrient deficiencies, growers can ensure healthy plant growth and maximize fruit production.

For more information on hydroponic blueberry cultivation and optimizing growing solutions, you can ask our experts.

References:

- Red Agricola, (2017, Marzo). Agrosystems trae innovación productiva a Chile: Cultivo de arándanos en maceta de fibra de coco. https://redagricola.com/

- Jiang, Y., Zeng, Q., Wei, J., Jiang, J., Li, Y., Chen, J., & Yu, H. (2019). Growth, fruit yield, photosynthetic characteristics, and leaf microelement concentration of two blueberry cultivars under different long-term soil pH treatments. Agronomy, 9(7), 357.